We are a leading manufacturer of Vibrating screens with advanced technology and with Optimum efficiency for aggregates, coals, processing industries & food industries.

| Model | Screen Size (mm) | Screening Area (Sq.m.) | No. of decks | Motor Power | Capacity (TPH) |

|---|---|---|---|---|---|

| IVS 1650 | 1500X5000 | 7.5 | 1,2,3,4 | 10/15/20 | 250 |

| IVS 1855 | 1800X5500 | 9.9 | 2,3,4 | 15/20 | 400 |

| IVS 2060 | 2000X6000 | 12 | 2,3,4 | 30/40 | 600 |

| IVS 2070 | 2000X7000 | 14 | 2,3,4 | 30/40 | 750 |

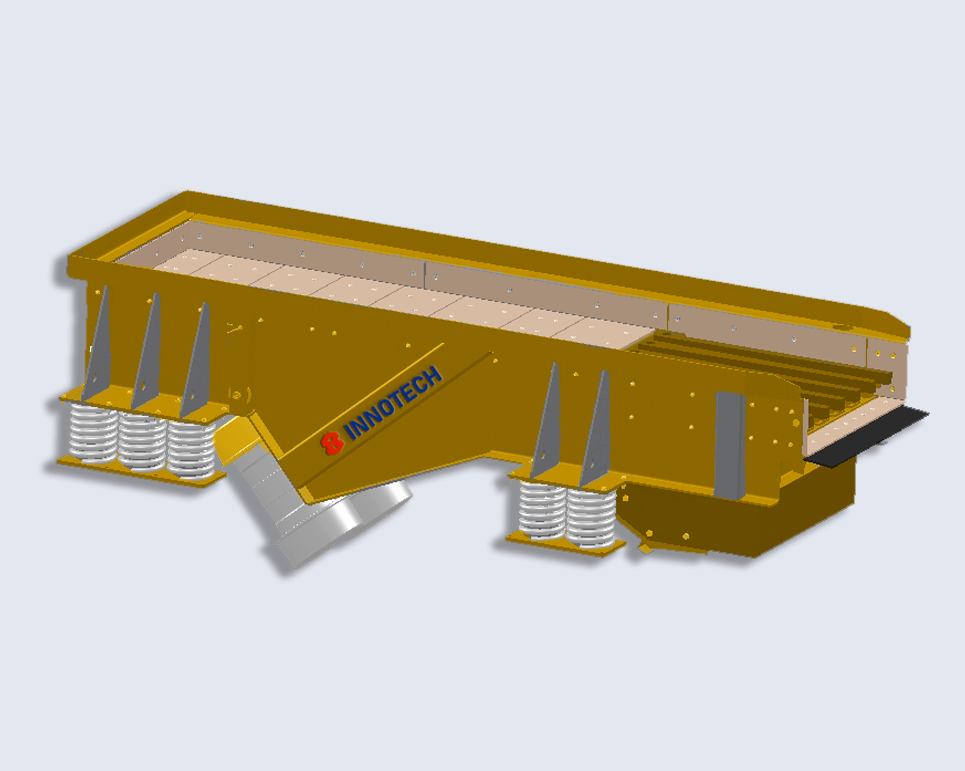

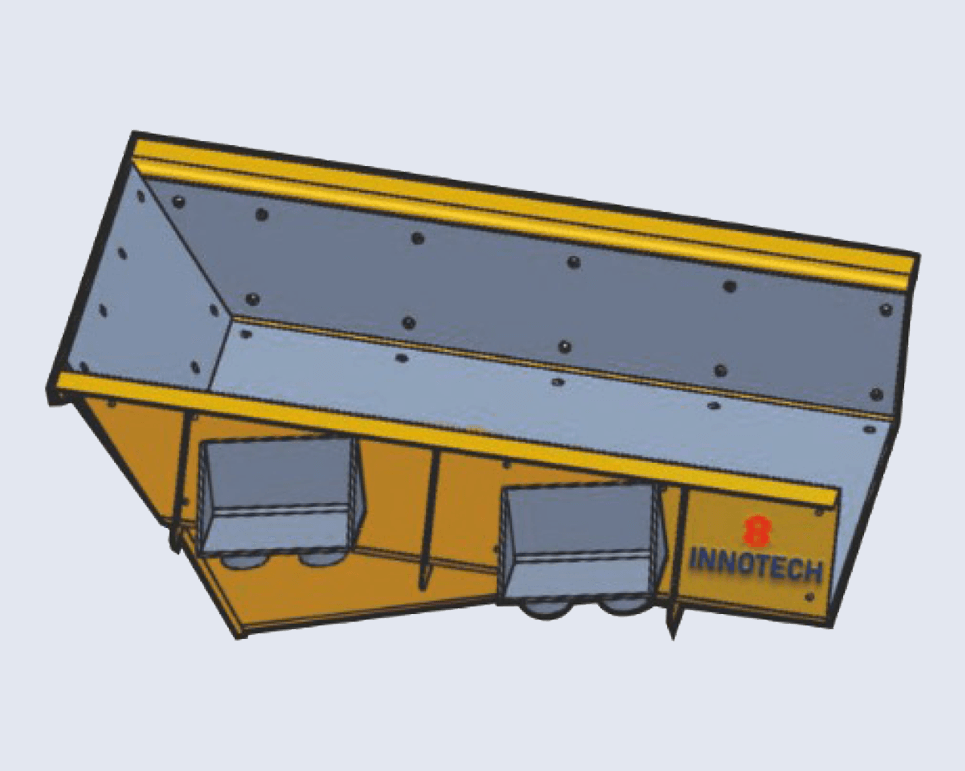

We are leading manufacturer of Vibrating screens with advanceed technology and with Optimum efficiency for aggregates, coals, processing industries & food industries.

| Model | Tray Dimension | Drive Mechanism | Power (HP) | Capacity TPH | Top Feed Size (mm) |

|---|---|---|---|---|---|

| IGF 1245 | 1200X4500 | Vibro Motor | 2x7.5 | 400 | 700 |

| IGF 1555 | 1500X5500 | Vibro Motor | 2x10 | 600 | 700 |

Adding ingredients, the feeding quantity can be adjusted conveniently and steplessly by adjusting the eccentric block.So, whether you are dealing with bulky, chunky material, or more delicate particles, vibratory feeders can get the job done.This flexibility in design, process, and utility can make vibratory feeders a great option for most production systems. The vibrating feeder is widely used in metallurgy, mineral processing, building materials, chemical, abrasive and other industries in the crushing, and screening equipment.

| Model | Screen Size (mm) | Motor Power | Capacity (TPH) |

|---|---|---|---|

| IVF 1015 | 1000x1500 | 2 x 1.5 | 100 - 250 |

| IVF 0811 | 800x1100 | 2 x 4.5 | 80 - 100 |